Tired of waiting too long for your slag analysis?

Fast and accurate metal alloy identification

AlloyChecker is designed for manufacturing, quality control, and recycling, it ensures reliable material identification and compliance with industry standards. Its lightweight handheld design and intuitive interface make it ideal for on-site sorting and PMI jobs. Experience precision and convenience with AlloyChecker.

Key Advantages:

AlloyChecker lightweight handheld design and intuitive interface make it ideal for on-site sorting and PMI jobs.

AlloyChecker Display

AlloyChecker Probe

The AlloyChecker provides results just in seconds—much faster than XRF. Press the start button and in 1 (one!) second you will see the results.

AlloyChecker is a handheld Laser-OES Analyser for multiple applications with support of the wide range of elements, including light ones.

Lower your operational costs by faster analysis, no sample preparation and zero argon consumption. It makes AlloyChecker a great investment!

Easy to use!

Our handheld analytical device is designed for maximum portability, allowing users to perform Sorting and PMI analysis with ease in any environment.

Powerful features from A to Z, both - advanced and user-friendly.

Patented solutions, cutting-edge design, and reimagining spectrometry from the ground up.

A team with decades of experience driving OES innovations. Today, we proudly transform this heritage into the future of OES.

AlloyChecker Features

You never want to miss again...

Ultra-Fast Analysis

Get your analysis results in one second! You will never want to miss this. Boost your effectiveness with AlloyChecker.

µBurnspot

With its micro-burnspot, AlloyChecker comes close to NDT. Now you can analyze finished products without leaving an ugly focal spot.

Zero Maintenance

Save time and money with zero maintenance. Focus on your analytical task and improve your efficiency.

Stand-alone, easy to use device

Its lightweight, ergonomic design ensures comfortable handling, while the intuitive user interface makes operation simple and efficient.

Efficient sample processing

AlloyChecker is designed for medium sample throughput. A traffic light system helps to avoid overload and ensures quality!

No argon required

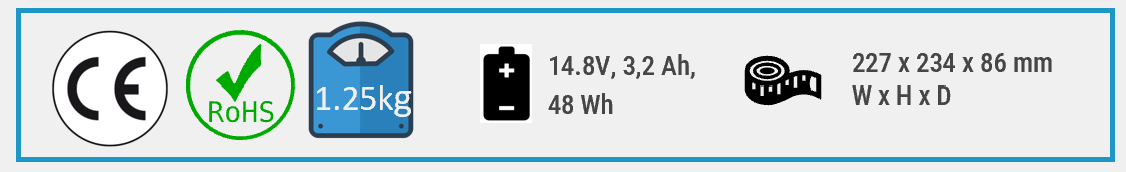

AlloyChecker applications work without argon. Just a little energy from the Li-ion battery is enough!

Inter-changeable batteries

Low battery can be quickly replaced with charged one. It reduces downtime and enhances device convenience.

Unrestricted "light elements" detection

AlloyChecker uses laser OES and has no restrictions in terms of "light" elements. Consequently, elements such as Li, Be, Mg, Al, Si are possible – all in 1 second!

Our customers are working in:

Recycling Application

Aluminium Scrap Sorting

Quality Control Application

PMI for Steels

Analytical Application

Light element analysis for Si, Al, Mg, Li, Be

AlloyChecker software offers an intuitive interface for enhanced user experience.

Key Benefits:

Whether in the field or the lab, our software ensures accuracy, efficiency, and ease of use.

Advantages of AlloyChecker:

One of the most powerful functions built in the AlloyChecker is the ability to perform calibration easily and by yourself.

Two inter-changeable batteries are included in the standard delivery. It decreases downtime and allows seamless use of the device.

Explore our latest blog posts to see how state-of-the-art OES solutions are speeding up results, improving accuracy, and transforming the industry:

Tired of waiting too long for your slag analysis?

The techniques Laser-OES and Spark-OES (Optical Emission Spectrometry) are both used for elemental...

On November 6th and 7th, 2024, Otto Fuchs KG in Meinerzhagen welcomed the members of Aluminium...

AlloyChecker and all accessories can be safely transported or shipped in the included transport case. Accessorises set may vary and depends on your purchase.

Transport case, front side

Transport case, back side

Packed AlloyChecker

Connect AlloyChecker to a mini-printer using Bluetooth.

.png?width=2000&height=1500&name=Adobe%20Express%20-%20file%20(4).png)

Available analytical applications:

Steel / Iron

Included elements: Si, Mn, Cr, Mo, Ni, Cu, Al, Co, Nb, Ti, V, W, Fe.

Aluminium

Included elements: Si, Fe, Cu, Mn, Mg, Cr, Ni, Zn, Ti, Ag, Be, Pb, Sn, Sr, Zr, Al and Li - optional.

Copper

Nickel

Zinc