Tired of waiting too long for your slag analysis?

QLX1 - versatile Laser-OES

The most efficient and effective way to analyse, identify & sort your material

The QLX1 is a versatile Laser-OES instrument designed for rapid, accurate elemental analysis. Combining advanced laser technology with intuitive software, the QLX1 delivers precise, real-time results for a wide range of materials.

Key Advantages:

Compact and easy to use, it’s the ideal solution for industries seeking high-performance analysis in a cost-effective, portable system.

The QLX1 provides fast results in 3s —much faster than XRF, including light elements like Al, Si, Mg, etc. Faster results - more analyses.

No matter which element you are looking for, it is there. For steels, QLX1 can also do C, P, S, N, Sn, As, B – everything in 3 seconds.

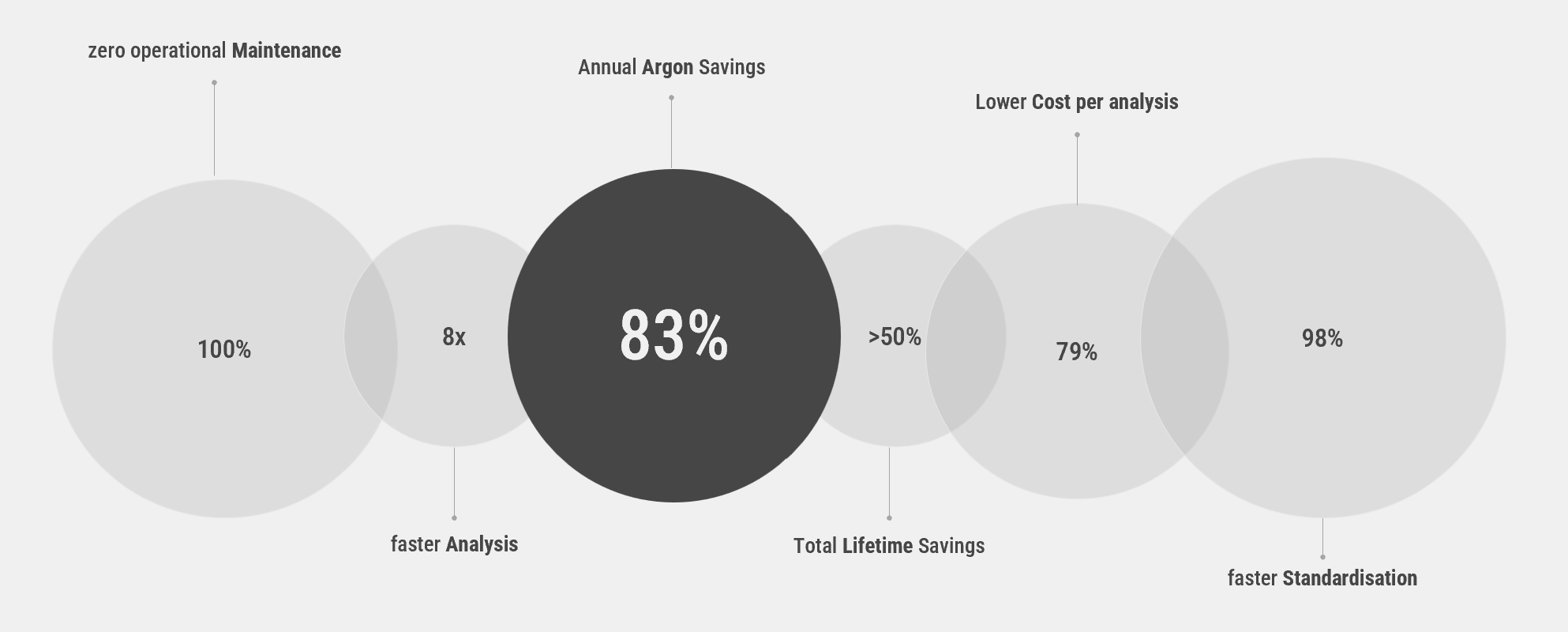

Lowest operational cost in the industry: faster analysis and standardization, lesser sample preparation and significantly reduced argon consumption makes QLX1 a great investment!

Easy to use!

It’s the ideal solution for industries seeking high-performance analysis in a cost-effective, portable system.

Cutting-Edge Software, Simplified

Powerful features from A to Z, both - advanced and user-friendly.

Innovation at High Speed

Patented solutions, cutting-edge design, and reimagining spectrometry from the ground up.

Decades of OES Experience

A team with decades of experience driving OES innovations. Today, we proudly transform this heritage into the future of OES.

QLX1 Features

that provide added value to your processes...

Ultra-Fast Analysis

Press the start button and in 3 seconds you see the results. You will never want to miss this. Boost your effectiveness with QLX1.

µBurnspot

With its micro burnspot of 0.1 mm QLX1 is near NDT.

Now you can analyse finished products without leaving an ugly mark on it.

Tricky Samples

QLX1 handles any sample shape with ease. No special adapters, no special prep. Quickly analyse wires, foils, and odd shapes.

Zero Maintenance

Save time and money with zero maintenance. Focus on your analytical task and improve your efficiency.

Exceptional UX

Experience QLX1 – intuitive, simple, and designed to make your work feel lighter and easier than ever.

High Sample Thruput

QLX1 is a work horse. Analyse more samples in less time. No worries: the instrument does not heat up, no real limit to the number of samples!

Argon

Some of QLX1 applications work even without any argon. And where we need it, it‘s only a fraction of what you used before. Lower your cost!

All Elements

No matter which element you are looking for, it is there. Light elements, UV elements like C, P, S, As, B – everything in 3 seconds.

New Applications

QLX1 better supports all kinds of metal applications. But laser-OES, unlike spark, is not limited to metals. Let‘s explore your application.

Our customers are working in:

QLX 4.0 streamlines operations and enhances productivity in both production and analytical workflows. Its advanced features ensure precision, security, and ease of use, making it a vital tool for daily processes.

Key Benefits:

QLX 4.0 adapts to your needs, driving efficiency at every stage.

Advantages of QLX1

Advanced Access Control

Rapid results

No maintenance

Very quick standardisation w/ single sample & no sample preparation

Very quick start-up time

No argon mode or ultra-low consumption

Fast return on investment

Explore our latest blog posts to see how state-of-the-art OES solutions are speeding up results, improving accuracy, and transforming the industry:

Tired of waiting too long for your slag analysis?

The techniques Laser-OES and Spark-OES (Optical Emission Spectrometry) are both used for elemental...

On November 6th and 7th, 2024, Otto Fuchs KG in Meinerzhagen welcomed the members of Aluminium...

Refillable 0.35l bottle contains 70l of Argon, which is enough for <1500 measurements.

Backpack System for easy transport and hands-free

movement.

The secure and comfortable way to move around your QLX1. Ideal also for flight

transportation.

Available analytical applications

Steel / Iron

Ferrous/Steel applications contain the following elements: Fe, Si, Mn, P, S, Cr, Mo, Ni, Cu, Al, Co, Nb, Pb, Ti, V, W.

Aluminium Alloys

Aluminium applications contain the following elements: Al, Fe, Cu, Mn, Mg, Cr, Ni, Zn, Ti, Ag, Co, Sn, Sr.

Copper Alloys

Copper applications contain the following elements: Cu, Zn, Pb, Sn, P, Mn, Fe, Ni, Si, Mg, Cr, Al, As, Ag, Co, Bi, Sb, Nb, Se.

Nickel Alloys

Nickel applications contain the following elements: Ni, C, Mn, P, S, Si, Cu, Cr, Mo, W, Fe, Al, Co, Mg, Nb, Pb, Ti, V, Ni.

Zinc Alloys

Zinc applications contain the following elements: Zn, Al, Cd, Cr, Cu, Fe, Mg, Mn, Pb, Si, Sn, Ti.

Tin Alloys

Tin applications contain the following elements: Sn, Ag, As, Au, Bi, Cd, Cu, Fe, In, Ni, Pb, Sb, Zn.

Unnamed Apps

Your application is not mentioned?

Contact us and share your requirements and we will check what solution we can provide for you.