Decisions Under Time Pressure Tuesday, 14:32. A winter morning in a German steel mill. The control...

Portable Alloy Analysis for Recycling, Metal Trade and QC with Laser-OES

Accurate alloy analysis is a decisive factor in today’s global metals industry. Whether in recycling yards, metal trading operations, production quality control, or inspection services, fast and reliable material verification directly impacts profitability, safety, and compliance.

Modern laser-based optical emission technology enables high-performance analysis not only in laboratory environment, but also directly in field conditions — without compromising analytical capability.

Why Field-Capable Alloy Analysis Is Increasingly Important !

In global supply chains, materials are inspected at multiple stages:

- Incoming material verification (PMI – Positive Material Identification)

- On-site inspection during construction or plant maintenance

- Scrap sorting and metal trading

- Final quality control before shipment

- Laboratory validation and documentation

Waiting for samples to be transported to a central laboratory can slow down operations and increase costs. A field-capable alloy analyzer allows immediate decisions — reducing downtime and logistical effort.

At the same time, laboratory-level precision remains critical for certification, traceability, and compliance with ASTM, DIN, ISO, and EN standards.

What Is Laser-OES Technology ?

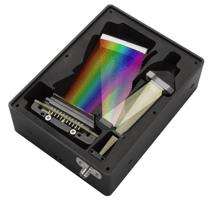

Laser-OES (Laser Optical Emission Spectrometry) is a variation of optical emission spectrometry.

Working Principle:

- A high-energy pulsed laser is focused onto the sample surface.

- The laser pulse ablates a microscopic amount of material, generating a plasma plume.

- Excited atoms in the plasma emit light at element-specific wavelengths.

- An optical system dispersed the light and quantifies the emitted spectrum.

Because each chemical element emits a unique spectral signature, the system determines the alloy composition rapidly and with high precision.

Advantages of Laser-OES for Field Applications

-

True Portability with Laboratory-Level Capability

Laser-OES instruments can be designed for rough field conditions, while still delivering analytical performance suitable for laboratory verification.

-

Fast Light Element Analysis

A major technical advantage is the rapid detection of light elements, like Li, Be, Mg, Al, Si. These elements are often difficult or slow to measure using alternative portable technologies. Laser-OES enables their analysis directly in field environments, supporting applications such as aluminum alloy differentiation and advanced material verification.

-

Near Non-Destructive Testing

The laser ablates only a microscopic spot. The impact on the component is minimal, making it suitable for inspections where structural integrity must be preserved.

-

Minimal to No Consumables

Unlike traditional spark systems, laser-based analyzers do not require electrodes, reducing maintenance and operating costs. Laser-OES systems operate with build-in argon supply or do not require it at all, which simplifies field operation and lowers infrastructure demands.

-

No X-Ray Radiation

Unlike XRF analyzers, laser-OES does not generate X-rays. This means:

-

No radiation licensing requirements *

-

Simplified international transport

-

Increased operator safety

-

Fewer regulatory constraints *

* Laser safety regulations may apply in certain countries

-

-

Carbon & Nitrogen Detection Capability

For steel and alloy certification, carbon measurement is essential. Laser-OES technology enables carbon analysis — a key advantage over many portable XRF devices. Even the measurement of nitrogen for verification of Duplex steels is possible with this technique.

-

Fast Decision-Making On-Site

Immediate alloy identification supports maintenance teams, inspectors, and quality managers in making informed decisions directly at the point of use.

Choosing the Right Alloy Analyzer System

When evaluating an alloy analyzer, consider:

- Required element range (especially light elements like C, N)

- Detection limits and precision

- Calibration flexibility

- Throughput requirements

- Maintenance and operational costs

- Regulatory and documentation requirements

- Integration with LIMS or ERP systems

Examples of a Field-Optimized Laser-OES Solutions

1. AlloyChecker

A representative system is the AlloyChecker, primarily designed for field applications while also being suitable for laboratory use.

It combines:

- Rapid 1-second assessment of metals

- Compact design for on-site alloy analysis

- No consumables

- User-friendly operation

- Capability to support both PMI inspections and laboratory validation

This dual-use flexibility makes it attractive for companies operating internationally, where material verification may occur in warehouses, production facilities, field inspection, or laboratory environments.

2. QLX1

While designed as a portable instrument for on-site use, it can also be integrated into laboratory environments, offering flexibility for inspection, PMI and metal sorting.

It combines:

- High analytical performance comparable to classical spark OES systems

- Precise carbon identification for steel and alloy certification

- Portable design with the option for laboratory operation

- Minimal argon consumption with changeable mini-flasks

- Reduced infrastructure requirements compared to traditional stationary systems

- SQL database integration capability for structured data storage, traceability, and compliance with international quality standards

This combination of analytical depth, carbon capability, operational flexibility, and digital integration makes the QLX1 particularly attractive for companies that require laboratory-grade alloy analysis both in the field and within controlled lab environments.