QLX9 - High-Performance Laser-OES

Redefining Slag Analysis

The QLX9 represents the top-tier model in the QuantoLux product portfolio, offering unparalleled performance in the analysis of non-conductive materials like slags, salts, and minerals. This compact OES analyzer eliminates the need for sample preparation, streamlining workflows and enhancing productivity.

Key Advantages:

- Exceptional Speed – Completes analysis in 1/10 of the time compared to traditional methods.

- Simplified Process – User-friendly design minimizes operational complexity.

- Cost Efficiency – Reduces labor and eliminates the need for prep equipment.

- Durability – Built with wear-free components for long-term reliability.

- Compact Design – Small footprint ideal for limited lab space.

The QLX9 is the ultimate solution for fast, cost-effective, and reliable material analysis.

Why using the QLX9?

Faster results

The QLX9 provides results in 20 seconds—10 times faster than XRF—reducing delays, labor, and enabling continuous monitoring. It’s the fastest analyzer on the market, driving efficiency and better process control.

More results

The QLX9 simplifies measurements, making results easier and faster to obtain. After implementation, sample throughput often doubles or triples, leading to close-meshed analysis and more efficient monitoring.

Better results

Sample prep. can cause over 50% of analysis errors. Sample prep-free OES slag analysis saves time, reduces errors, and allows quick, repeated measurements for outlier elimination and improved precision.

The QLX9 in action

Redefining Simplicity and Speed

Uniquely QuantoLux

-

Cutting-Edge Software, Simplified

Powerful features from A to Z, both - advanced and user-friendly.

-

Innovation at High Speed

Patented solutions, cutting-edge design, and reimagining spectrometry from the ground up.

-

Decades of OES Experience

A team with decades of experience driving OES innovations. Today, we proudly transform this heritage into the future of OES.

QLX9 FAQ´s

QLX9 Features

You never want to miss again...

-

Ultra-fast analysis

Start the analysis and receive results within in under 20 seconds. A speed you will never want to miss again!

-

Little to no sample prep

QLX9 does not require tedious sample preparation. It can be done with no experience, directly on-site.

-

Exceptional UX

Experience QLX9 – intuitive, simple, and designed to make your work feel lighter and easier than ever.

-

Min Maintenance, Max Uptime

The wear-free design, combined with quick weekly maintenance in under 10 minutes, guarantees high uptime and reduced operational costs. This ensures smooth performance with minimal interruptions.

-

High sample through-put

QLX9 is a work horse. Analyse more samples in less time. Instrument does not heat up, no real limit to the number of samples!

-

No Argon

All QLX9 Applications work without Argon, which lowers costs and simplifies daily life

-

All Elements

Contraints due to elemental weight are not relevant for OES. Analyse all elements in your slag in one go.

-

New Applications

QLX9 supports slags and ferroalloys applications. Further applications, such as Black Mass or Cement will be available soon!

Download more information here

Typical QLX9 setup positions

In the lab or at the shop floor:

Place the instrument where it best performs for your application.

Laboratory

The QLX9 can be placed in laboratory like a classical spectrometer and can be used in Quality Control or in research and development activities within steel plants, providing valuable data for innovation and process improvements.

Control Room

The QLX9 is built for the harsh conditions of steel mills. Unlike lab equipment, it can be installed near the control room, enabling quick, data-driven adjustments. This reduces response time and improves process efficiency. The QLX9 delivers accurate results, unaffected by dust or vibrations.

At-Line

For the at-line applications, which require to perform analysis in close proximity of furnace, QLX9 HD (Heavy Duty) option is available.

It is designed to withstand extreme conditions of smelting plant and ideal for rapid analysis of slags!

"Making a difference in the steel industry has been my motivation since day one of this exciting journey."

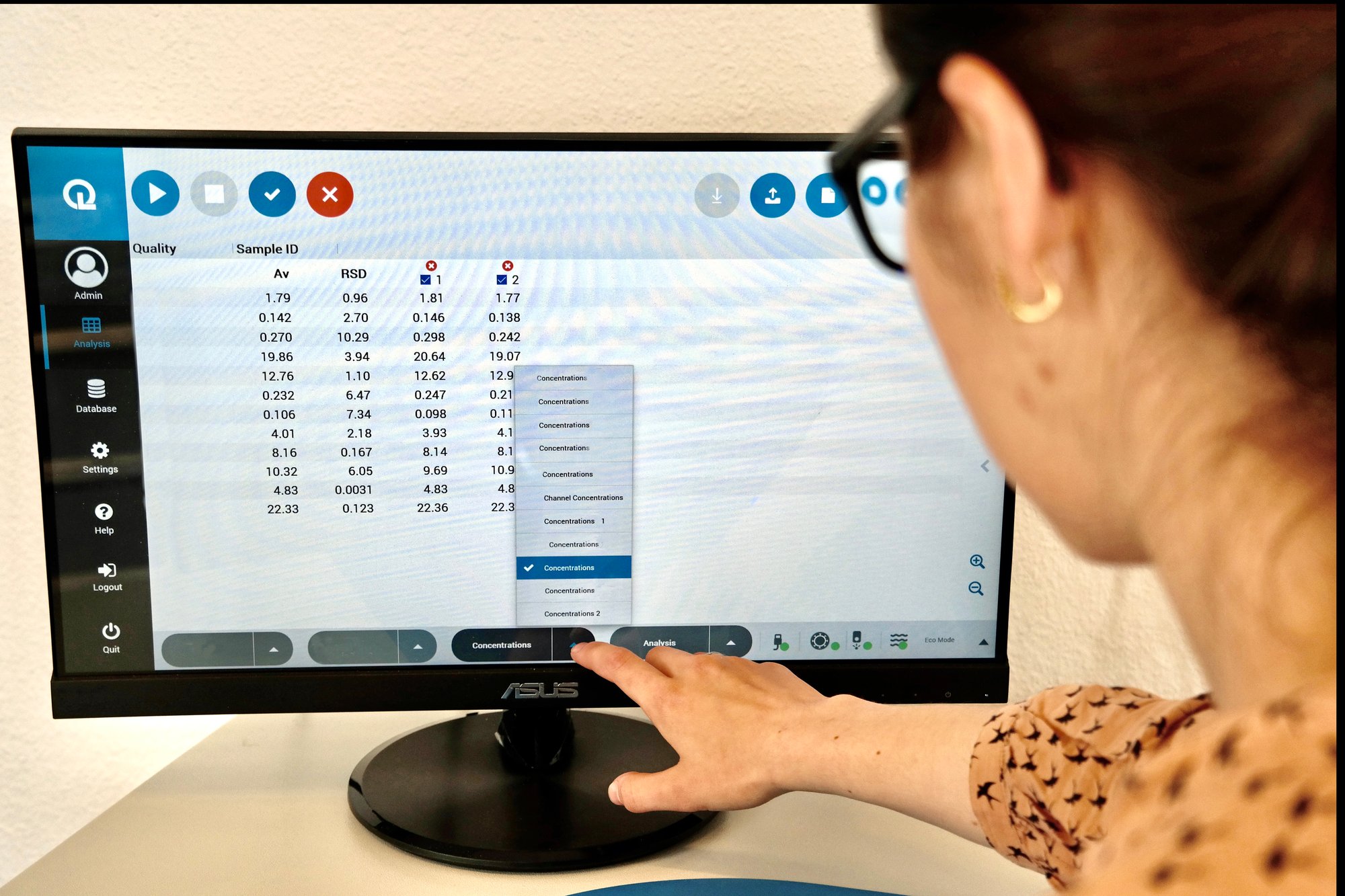

Innovative Software!

QLX 4.0 streamlines operations and enhances productivity in both production and analytical workflows. Its advanced features ensure precision, security, and ease of use, making it a vital tool for daily processes.

Key Benefits:

- Intuitive Interface – Simplifies workflows, reduces training, and boosts productivity.

- Advanced Access Control – Enables secure, compliant, user-specific rights management.

- Precision Calibration – Delivers highly accurate measurements to maintain quality and consistency.

QLX 4.0 adapts to your needs, driving efficiency at every stage.

Discover the Future of Slag Analysis

Explore our latest blog posts to see how state-of-the-art OES solutions are speeding up results, improving accuracy, and transforming metallurgy.

XRF vs. OES slag analysis

Explore the pros and cons of X-Ray Fluorescence (XRF) and Optical Emission Spectroscopy (OES) in slag analysis. Learn how each method measures composition, accuracy, speed, and cost, so you can choose the best solution for your needs.

Read more...

QLX9 Proves Its Worth in Tough Conditions

Discover the latest slag analyzer commissioned by the QuantoLux team and learn why the customer chose this state-of-the-art solution. Understand their motivation for upgrading to advanced analysis and see how cutting-edge OES technology is shaping the future of materials characterization.

Read more...

Built for Harsh Environments

In secondary metallurgy, extreme temperatures and dust are the norm. Yet the QLX9 slag analyzer, installed right next to the control room, excels. Operated by the control-room team, it provides real-time slag data, helping fine-tune processes and improve quality. The QLX9 proves efficiency can thrive—even in the harshest conditions.

Read more...Options: The QLX9 Heavy Duty (HD)

Redefining Simplicity and Speed

Get even Faster Results: QLX9HD

If bringing slag samples to your on-site lab or control room takes too much time, the QLX9 HD (Heavy Duty) is the perfect solution. This robust system comes in a 1.5mm steel, powder-coated housing with AC and insulation. Designed for tough environments, it allows you to place the fastest slag analyzer closer to the furnace, saving time and boosting efficiency.

The QLX9 HD features a specially designed sample input door to minimize dust contamination during measurement. With the touch-based QuantoLux software, you can access all important functionalities easily—no mouse or keyboard needed. This makes the device simple to use even in busy or dusty areas.

For safety and control, all doors are lockable, so only authorized professionals or supervisors can access the device. Built with durability and user convenience in mind, the QLX9 HD is a reliable solution for faster and more efficient slag analysis.

Sample Handling Station

To address these challenges, we developed the Sample Handling Station – designed to simplify slag sample collection, improve accuracy, and enhance safety. This station supports slag samples collected by bar or spoon, streamlining the process.

How It Works:

-

The sampling device can be tapped against the station’s slide.

-

Slag dislodges and slides into the collection shovel/bin.

-

This prevents residual slag from contaminating subsequent samples – a common issue when bars are tapped on the floor.

-

It also eliminates the need to pick up hot slag from the ground, significantly improving health and safety.

Ergonomic Advantages:

-

The collection shovel/bin is positioned at approximately 20 cm height, reducing strain.

-

Samples can be handled with one hand, offering better ergonomics compared to traditional two-handed sweeping methods.

Efficiency Gains:

Once collected, the sample is processed through a manual crusher, crushed, dosed, and prepared for analysis. This streamlined workflow not only enhances precision but also saves valuable time.

With the Sample Handling Station, we aim to elevate operational efficiency, ensuring consistent and reliable results for the steel industry.